Many of you are wondering about the same things:

-

How to choose a Laguiole knife ?

-

Which handle should I choose for my Laguiole ?

-

Which type of blade should I select ?

So, to answer all your questions, we have asked our master cutlery-makers to contribute so we could bring you all the answers you need!

Choosing a knife.

Choosing a knife – general remarks.

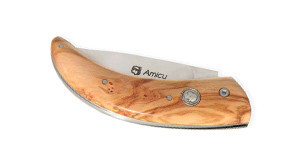

How to choose your Laguiole? Which pocket knife should you choose? If you want to buy a folding knife, several criteria should be taken into account when making your decision. First, its size, which usually varies between 7 and 13 centimetres. The size of the palm of your hand is a decisive factor. Depending on the use of the folding knife, there are several types of blades you can choose from, for example a carbon blade, both practical and cheap. The Sandvik blade is the most common and the toughest. The blade should be hard and robust. Finally, the handle will give your knife its shape and design.

The handle can be made out of rosewood tree, abalone (shellfish), rosewood or olive tree depending on your budget and your wishes.

If the knife is used to eat or cook, it is worth noting that as well as a handle and a blade, a knife is made of other parts such as the scales. These are the external parts of the handle. Scales are made out of wood, stamina, resin, bone… They are attached to the knife and give it its distinctive look and unique style.

How should I choose the size of my Laguiole knife ?

A 9 cm knife is recommended for a pocket or handbag knife.

-

Size folded: 9 cm.

-

Size unfolded: 17 cm.

A 10 cm knife fits into all hands.

-

Size folded: 10 cm.

-

Size unfolded: 20 cm.

An 11 cm knife fits into all hands.

-

Size folded: 11 cm.

-

Size unfolded: 20 cm.

A 12 cm knife is recommended for larger men hands.

-

Size folded: 12 cm.

-

Size unfolded: 22 cm.

All there is to know about handles.

-

What is the difference between pressed horn and horn tip ?

There are two types of horn handles :

-

The pressed horn version : it is made out of the hollow part of the horn and has to be hot-pressed to fill in the ‘gap’ inside and fashion handle scales.

-

Horn tip is much tougher than pressed horn, due to its being naturally compact. Horn tip handles may flake over time due to heat or humidity, which is why these handles should never go in a dishwasher.

-

What makes the toughest handles, wood or horn ?

Wood generally copes better with temperature changes and the passing of time. Even if both materials can be given a new lease on life by gently sanding them and giving them adequate care.

-

Where does the horn in your knife handles come from ?

We use several types of horn:

-

Cow horn and ram horn .

Comes from the solid higher section of the horn. It can be white (cow or ram horn) and go from completely white to dark beige (‘Flamed horn’). It can be dark (buffalo horn) ranging from dark beige to solid black.

-

Antler handles.

Deer, roe, moose or wapiti antlers have been used to craft tools and weapons since the dawn of times.

Deer grow and loose antlers every year, which means that no harm is done to the animal. Antler is a resistant, beautiful and reasonably-priced material. Antlers are both tough and easy to use, which is why they are a popular choice for utilitarian designs.

-

What are the different handle materials ?

There are numerous available handle materials for Laguiole knives :

-

wood

-

stamina (stabilized wood)

-

paperstone

-

aluminium

-

horn

-

resin

-

stone…

-

Why choose stamina for a Laguiole knife?

Stamina is made of coloured wood inside of which fully tinted resin has been injected. Stamina is a super resistant material: it is able to withstand the test of time and rigorous conditions (dirt, humidity, shocks…) much better than a standard wooden handle. Above all stamina keeps its shape no matter what while at the same time offering you perfect looks and superb colours. It is ideal if you would like a wooden handle without the drawbacks of one.

All there is to know about blades.

-

Which blade for my Laguiole ?

It all depends on the intended use and how much effort you are prepared to make to look after your knife.

Carbon is susceptible to rust and must therefore be thoroughly wiped after use. On the other hand, steel does not rust and requires less care.

-

Which type of steel do you use for your blades ?

Most of the time, we use steel and stainless steel.

-

What is the difference between carbon and stainless steel ?

Unfortunately carbon rusts and turns dark over time. Such blades therefore require meticulous care. They can’t be left in contact with humidity. However, compared to stainless steel, carbon re-sharpens much better.

If you take good care of your knife and wipe it meticulously after each use, the nit is preferable to choose a carbon blade.

If you are giving a knife as a gift to someone who has no particular knowledge of knives, then it is better to choose a standard stainless steel blade.

Choosing a carbon blade occurs during step 4 of our customizing module here.

-

Do you sell more carbon or stainless steel blades ?

85 % of the knives we sell feature a stainless steel blade and 15% a carbon blade. These figures are easily explained : stainless steel knives are easier to look after : they are a smart buy !

A carbon blade is exactly the same price as a stainless steel blade. In fact, you can order one for all of our knives. We only assemble carbon-bladed knives upon special request. The only change concerns processing time, which is about 2-weeks longer since it is a special manufacturing process.

-

What are the existing grades of steel for blades?

The most famous steel for knife blades is the 440 steel which the amateurs of Opinel and Laguiole among our grandfathers knew and loved well. That grade was very easily sharpened using any sharpening stone or rod. But the classic 440 steel blade darkens with time and one should polish it, shine it, never ever washi t under water and wipe it regularly with a cloth to avoid rust.

In those days, the darkening of the blade could dirty people’s food and give it a metallic aftertaste, but at that time no one paid attention to this, and people made do.

Since then, steel alloys have evolved and the metalworking industry has created steel which is better suited to everyday uses. All this to say that the 440 steel, now called 440 stainless steel is the modern version of our forefathers’ steel. It is also currently the most common alloy. The white stainless steel blade does not darken, it is not as easy to sharpen, but in comparison to the quality gained, this drawback is minimal.

Then came the 12C7 steel. It is very popular right now since it offers the best of both worlds without the drawbacks (Easy to maintain and no need to worry about rust)

Note : As far as Laguiole pocket knives are concerned, a 440C steel blade still guarantees top quality for frequent everyday use.

-

Understanding the hardness of a blade.

Rockwell HRC scale : test which consists in measuring the depth of penetration of a steel load to measure the hardness of metals

-

53-54 HRC and above are considered decent hardness values for a knife blade

-

Above 58-60 HRC, this is a very high quality blade

Do keep in mind, though, that a very hard blade will also be more difficult to sharpen.

-

What is a guilloched (engraved) blade ?

-

What is a stop pin ?

Although ubiquitous in days gone by, the distinctive snap which accompanied the folding a Laguiole knives is now a thing of the past.

In fact, in those days, Laguiole knives were not equipped with stop pins. As a result, the blade kept hitting the locking mechanism too hard and quickly became blunt. The edge of the blade needed to be re-sharpened pretty regularly.

To prevent this, modern Laguioles are fitted with a stop pin locking mechanism.

A stop pin is a small metallic component inserted on the locking mechanism, near the heel, which saves your blade from snapping shut. Thus equipped, the edge of your blade no longer hits the locking mechanism when you fold your knife. The snapping noise can still be heard (for the nostalgically minded among us) but the blade is now protected.

A Laguiole knife should also ‘ponceter’, that is to say it should show correct tension in the locking mechanism. It is easy to check: all you have to do is gently press on the folded blade. You should feel a slight elasticity, proof of a correctly balanced tension between blade and locking mechanism. When you look at the other side of the knife, you can see that the blade is perfectly centred,/ in between both liners. A true work of art !

Questions regarding Damascus steel.

-

What is Damascus steel ?

This expression refers to the shimmering moiré pieces of cloth woven in the city of Damascus, not to the blades that were being forged there.

Damascus steel forging is a way of refining iron through a succession of hammering, folding and drawing out operations. These steps aim to get rid of the impurities in the metal. A composite material is therefore created with a succession of more or less homogeneous layers, usually iron, steel or nickel combinations.

The heterogeneous texture produces rather exceptional mechanical qualities, because Damascus steel can only partially be quenched (neither iron nor nickel quench). As a result, the metal resists breaks by diffracting shockwaves.

-

What is a Damascus blade ?

There are several techniques to forge Damascus steel:

-

The western or Merovingian technique.

It was used by Merovingian blacksmiths, this process, which consisted in changing the shape of the metal, inexplicably got lost towards the end of the 11th century.

-

Eastern Damascus steel or fusion Damascus steel is the epitome of Damascus steel.

Wootz is to blacksmiths what the Philosopher’s Stone is to alchemists, but despite continuing efforts, it seems that no one has so far been able to recreate this extremely complex crafting process.

-

Japanese Damascus is the type which is found nowadays.

Is forged through hammering and drawing out.

Originally in the thousands, the layers constituting sword blades have progressively gone down to a few hundred. Indeed, any more and the texture is too dense and the acid etching no longer produces aesthetically pleasing results.

Beyond the undeniable mechanical properties of Damascus steel blades, it is important to emphasize their beautiful aspects.

The composite quality of the material hides numerous anamorphic potentialities which depend both on the folding and drawing out, as well as the deep work (for example sculpting) of the metal.

Once the Damascus steel element has the desired shape, all that is left to do is to submerge it in acid which blackens only carbon and thus reveals the structure of the metal.

Stainless Damascus steel, nevertheless highly carbon-loaded is made from powder steel (very fine grain, lasting edge) because the intrinsic mechanical quality of the metal allows for very hard quenching (up to 63-4 Rockwell) following cryogenization.

-

Are Damascus blades harder than standard blades ?

Objectively speaking, a Damascus blade is harder (63-4 Rockwell) than a standard blade ( 58-60 HRC), but always keep in mind that the harder a blade, the more complex it is to sharpen it.

-

How are Damascus blades etched ?

Once the Damascus element has been given its intended shape, all that is left to do is submerge it into acid which only blackens carbon and thus reveals the structure of the metal. Both the acids and the technique itself require mastery and specialized know-how, which also explains the price of Damascus blades.

-

Are there fake Damascus blades ?

There are doubtlessly counterfeiters who sell laser-engraved blades as Damascus steel blades, but they are putting a lot of effort into a disappointing process. However, yes, indeed, there are blades out there with a decorative laser or acid surface treatment.

During polishing, it is normal that the reliefs and patterns formed during the initial acid etching (which shows the structure of the different layers based on their composition) fade somewhat.

An iron perchlorate bath will allow you to perform etching without too much risk. We strongly advise against playing with acids, perchlorate being much less dangerous.

To identify a Damascus knife, price is also a good indicator. If your ‘Damascus’ knife costs in the region of 20-30 euros, no more (depending on the honesty of the seller), it is obviously not a real Damascus knife.

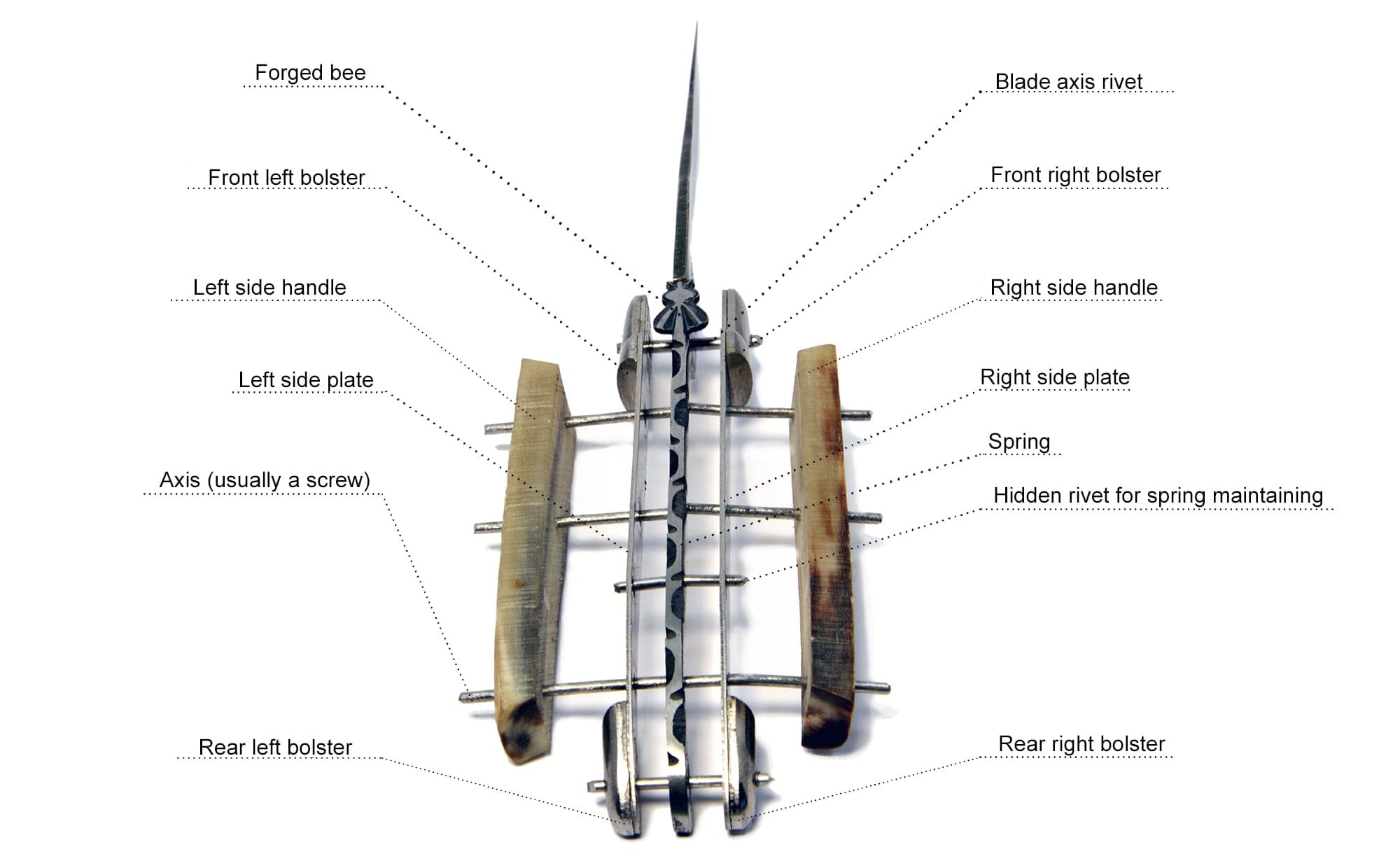

Bolsters, bees and springs.

-

What is the difference between a soldered or forged bee ?

The fly is a technical term which refers to the part of the spring which is against the blade when the knife is unfolded.

The bee shape on a Laguiole is a distinctive and traditional feature of a laguiole knife.

Before 1935, the bee was always forged, meaning that the spring and the bee were made out of the same piece of metal. This result was obtained by hot pressing a piece of metal.

With the development of industrial cutlery-making in France, soldered bees, results of a simpler and quicker process, appeared.

A forged bee is always more resistant than a soldered one, given that the technical qualities of a single piece of metal are by far superior to that of two elements soldered together.

As a result, soldered bees are present on the standard range of folding knives. Forged bees are found on high-end knives with sophisticated finishing touches.

-

Bee or Fly ?

The fly is a technical term which refers to the part of the spring which is against the blade when the knife is unfolded.

There is also a legend according to which Napoleon would have granted Aveyron cutlery-makers to use the bee as a token of their bravery in combat. Actually, the reason is more related to aesthetic and rhetorical reasons.

Even if the bee has a better reputation than the fly, the fly is first and foremost a technical cutlery-making word referring to the flattened part of the spring. It is the front end of the spring. It can represent something other than a bee, such as a horseshoe, a clover, a scallop, a fleur-de-lys or your own emblem (we can also customize this element upon request).

Now you know, you will be un-bee-table !

-

What is a spring ?

The spring is the central part of the handle allows the folding and unfolding of the blade. It is the steel element opposite the blade on a folding knife.

The most famous are the slip joints : the spring is lodged at the top of the handle between two liners and press on the heel of the blade to keep it open or folded.

Springs can be forged, chiselled and quenched, which gives them both hardness and flexibility. The spring is adjusted by a cutlery-maker so that the blade may be saved from hitting it in folded position.

Not all folding knives are equipped with springs which hold the blades in place. The Capucin, a very simple design, only has two nails, while the Piemont features a friction system supported by the position of the user’s thumb on the blade’s heel. As for the famous Opinel, a sliding ring ensures that the blade is locked in place.

General Anatomy of a Laguiole knife.

Customizing Laguiole knives.

Customizing can take various forms.

You can have your Laguiole knife custom-made and choose all its composing elements : size, with or without corkscrew, handle wood variety, horn, abalone, stone, spring type (the back of the knife), engraving on the blade. The processing time is given to you as soon as you are done selecting your options.

You can also choose a knife in the Actiforge shop and have the blade engraved with a message or a picture according to your wishes.

General questions on engraving.

In order to make your Laguiole truly unique, you can choose to have it customized. We offer many engraving options and pattern choices to make your blades one-of-a-kind.

-

How to choose the engraving on a Laguiole knife ?

It is only natural that you should want a unique knife, that is why our cutlery-makers offer a wide range of customization choices.

You can have your blade engraved with your initials, your first name, a special date or choose from one of the available symbols : zodiac signs, musical instruments, sports… It’s up to you.

Besides the blade, you can also have the spring engraved (back of the knife) with your first name, your last name or the name of your company and give it to your collaborators.

Did you know : we can also customize sommelier knives. Perfect if you are a wine producer or a wine merchant : your professional tool is engraved with your brand!

To each their own tastes, however you can ask for our advice and we will give you our honest opinion on the final look of your customized design.

-

How can I have my Laguiole product engraved ?

There are several ways of having your Laguiole product engraved.

We can have your knife customized with a name, a date or a photo by laser-engraving on the blade. It will not fade away. It is done on the blade of your knife or on the side of the lever on Laguiole sommelier knives.

We can also have your knife engraved with symbols:

Zodiac signs.

-

Love symbols: heart - cupid – interlocked hearts- yin / yang.

-

Regional emblems : Brittany, Alsace, Corsica, Auvergne.

-

Sports symbols: tennis - sailing - golf...

-

Musical motifs: violin – musical note...

-

Fantasy symbols : smile - butterfly – lucky clover.

You can choose both options. The knife will be customized with a name and a symbol.

-

How long does it take to have a knife engraved ?

![]() Engraving time depends on what you’ve selected.

Engraving time depends on what you’ve selected.

Engraving time for a name or short message laser-engraved on the blade (maximum 2 lines) : up to 24h after you place your order.

Engraving time for interlocked initials laser-engraved on the blade (maximum 3 letters) : up to 24h after you place your order

Engraving time for spring engraving (back of the knife) : 15 days

Engraving time for spring engraving (back of the knife) : 15 days

You can also send us a picture that you wish to have engraved. All you need to do is send it to us electronically, in JPG format. The best results are obtained via stylized renditions, without no background. 5 days are required for this engraving option.

Questions about engraving a blade.

If I choose to have a blade engraved with a first name – will it be on the right or left side of the blade ?

By default, the engraving is done on the left side, closest to the handle.

-

Is it possible to have both sides engraved ?

Yes, it is possible to have both sides of our blades engraved, but there is already teh ‘Laguiole’ mention on one side. We therefore recommend having the engraving on the side of the blade which is blank.

-

Can I have a Damascus blade engraved?

It is possible to have a Damascus steel blade engraved, but we advise against it. Indeed the Damascus pattern already adorns the blade – adding an engraving would only detract from its beauty.

It is technically feasible, but does not look good.

Questions about spring engraving.

It is possible to have your knife customized on the spring (back).

How can I have the spring (top) of my knife engraved ?

Letters are etched by hand onto the spring, upon request, before quenching. Then your knife is assembled with the components you selected.

You can order the engraving of your knife’s spring on the ‘knife customization’ page.

Can I have lower-case letter engraved on the spring or can you only do capital letters?

It is possible to have lower-case letters engraved, but we do not recommend it. Indeed the final appearance is too small for our liking. However, you are free to request it if you wish.

Looking after a Laguiole

Looking after a Laguiole

-

How should you look after your Laguiole knife?

Properly caring for your knife is important in order to give it a long life. Generally speaking, a folding knife’s handle should be wiped, because wooden handles dislike water.

As for cleaning the blade, it’ll have to be washed with a cloth and damp sponge after every use. Once you’ve washed the blade, you should meticulously wipe it dry.

Sharpening a blade is no easy feat for people who aren’t used to doing it. In fact, the most convenient solution is to sharpen with a sharpening rod, while following some rules such as:

Your sharpening rod’s steel should be at least as long as the blade of your knife.

To avoid any injury, you should keep your fingers behind the rod’s guard.

Lay the base of the knife’s blade on the steel.

Slide the blade along the rod all the way to the tip and hone both sides of the blade alternatively.

Care tips for handles

How should you care for your Laguiole’s handle ?

In order to keep your handle in good condition, regardless of their type, you should try to avoid significant temperature and hygrometry variations. Additionally, avoid washing them in water or worse, actually soaking them in any type of liquid. A damp cloth is sufficient for everyday care.

-

Maintaining handles of animal origins

There are several types of handles which come from animals:

-

Deer antlers

-

Horns (tips or )

-

Bones (Giraffe shinbone)

-

Teeth (warthog).

Horn is a delicate material which requires the utmost care while it is being shaped. It is also very quick to dry out in ambient heat. It should be moisturized with neatsfoot oil or some leather care product (either light or dark coloured depending on the type of horn). This will prevent cracking and retracting, particularly in the summer.

Handles made of horn, bone or ivory can be cleaned by rubbing some purified chalk into them.

-

Wooden handles maintenance.

Look after your precious woods handles by rubbing some rifle stock linseed oil onto them. You can also moisturize them to add to their shine : just pour some olive oil on soft cloth and gently wipe the handle down.

Did you know ? If a knife is regularly used, sweat from the palm of your hand is the best care product there is.

You can fix cracking by preparing a wood powder of a similar colour to the handle you wish to repair (either from the same variety of wood, or by tinting it). Then all you need to do is mix this powder with transparent glue and fill the cracks. Let it dry and rub some wax on it to make it shine.

If there was only one thing to remember about the care and maintenance of our pocket: Never ever put them in the dishwasher and store them in a dry place.

Maintenance tips for blades.

-

Storage and Cleaning.

Never leave your knife in contact with other objects : keys, cutlery… and do not keep it unprotected in your handbag. This is how you will damage the handle and the metal parts.

Get your knife a sheath to protect it from shocks and potential splashes. If you like to keep an eye on your finest blades, keep them in a locked display case – they will be safe from shocks and domestic accidents.

-

How to clean a Laguiole ?

Simply wiping your blade down with a damp cloth should be enough to clean it efficiently.

Depending on the type of blade, it may require more specific care.

Carbon blades : these blades may oxidize with time. To give it back its former beauty, rub a damp cork dipped in cold ash on your blade and admire the results : your blade is now perfectly clean. Until the next acidic food you’ll slice…

Damascus blades : In case of prolonged disuse, you may want to oil your blade to prevent a loss of contrast (using a non-acidic grease such as silicon grease for plumbers or white grease.)

-

Can knives go in the dishwasher ?

From the point of view of proper care, we strongly recommend NOT using the dishwasher for ANY of our Laguiole knives.

However, if you are dead set onto it, some can endure the dishwasher : resin or paperstone handled knives – but they will not stay beautiful for very long. The hot water dishwashers use will unavoidably cause damage to your knives. Forget about this sort of treatment if you love your knife.

-

How to shut a Laguiole ?

➫ Shutting a lockback Laguiole knife.

The traditional locking system is the lockback : when the blade is opened, it pushes the spine out until the notch on the spine and blade are hooked into place.

With knives fitted with a pump locking system, there is no point using force to fold the blade shut. Gently press with your left hand and let your right hand go with the blade (for right-handed people).

➫ Shutting a liner-lock Laguiole

To shut your Laguiole knife, just softly press on the pump at the back of your knife to free the blade which will then fold gently.

-

Caring for mobile parts and other metal parts of a knife.

Knives do not handle pocket or bag dust well. In fact, you need to get rid of small impurities in the pivoting system of your knife with mineral spirit (turpentine) and compressed air (such as a keypad cleaner). Then you may use a drop of oil in the locking system to make it as good as new.

All the other metal parts of your knife – steel, nickel silver and brass -will go back to their original shiny selves with some polishing paste and a cotton cloth! Simple and neat !

Repairing a Laguiole knife.

Unless you are yourself a cutlery maker, or well versed in knife restoration, do not attempt to fix your knife. You might cause irreversible damage in the trying.

-

How to have a Laguiole knife repaired ?

We have a manufacturing warranty on our knives, but we can repair a Laguiole knife which has had an accident (broken spring or blade, damaged handle etc.)

We do not repair counterfeit Laguioles.

We begin restoration once the quote has been paid.

Waiting time before we return your knife : 15 days to 1 month.

We provide the repairing and restoration services your knives require. So our cutlery-makers can :

-

Sharpen and hone.

-

Replace a blade.

-

Replace a broken or worn-out spring.

Our varied skills allow us to repair and sharpen your Laguiole knives and even some other knives you might own. For example, you could ask us to restore your grandfather’s knife so that you can give it as a present to your son. Do not hesitate to contact us to get a quote.

➫ Concerning Damascus blades, the restoration process usually consists in removing a layer of oxidation. The ai mis to give the blade its original aspect, for examples in cases when the pattern has faded out. Getting rid of rust on a Damascus blade can be achieved through chemical means such as the use of acids which can eliminate rust, even the most resistant kind. However, it is important to use gentle acids to avoid eating away at part of the metal on the blade. Acids such as phosphoric or nitric acids are very aggressive on the blades. In any case, it is better to seek professional help for such a delicate undertaking.

All about sharpening.

-

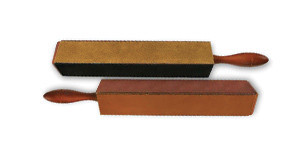

How to choose your sharpening stone ?

Use a rough grain sharpening stone for a rough or for a significantly damaged edge, then a fine stone for the finishing touch or for a precious knife (less risk if something does go wrong).

-

Tips on choosing a sharpening stone.

Important: ALWAYS use water, even on an oil stone. An Arkansas stone, sold with its oil bottle, will do beautifully well with water, much better than with oil… unless… if your stone has been used with oil in the past, then you’ll have to keep using oil because the stone’s pores will be saturated with oil and i twill be unusable with water.

➫ Arkansas stone, very tough stone which exists in ‘hard’ (grey) and ‘soft’ (white, slightly softer) versions. Ideal for an all-round use, if your edge isn’t too damaged (otherwise it’s going to be a time-consuming process). Remember : use water rather than oil.

➫ Vielsalm stone: Vielsalm is a small town in Belgium where this unique stone can be found : very fine and composed of minute garnets grains embedded in shale. It is used with water and does not last very long (it crumbles away), but the tiny garnet grains can sharpen even the toughest stainless steel. It also allows to obtain a razor-sharp edge, without leather, but it is rather expensive. You can smooth it down again by rubbing it against another piece of Vielsalm stone, of course using water.

➫ Diamond stone or DMT stone: Very convenient since it is unbreakable, it can be used without water (for emergencies) and almost anywhere (usually fits in your pocket). Its biggest drawback is its price, but it can be used on the toughest steel.

➫ Scythe stone, aka synthetic stone or 1,50 EUR stone. Practical for roughs, it gives a streaked and rough edge which does not really cut through anything and does not last long.

Good to know : A large stone will be easier to use, but also more expensive to purchase (which can quickly turn into unaffordable in the case of a Vielsalm stone).

In a nutshell, if you can only buy one whetstone, buy…. two !

➩ One Arkansas stone, rather easy to find, and which will give you impeccable or even razor-edges, if that is what you’re after.

➩ A 1,50 EUR stone from your local supermarket, for the roughs or the big jobs. If you damage or break it, you’ll get over it easily enough.

-

How to sharpen a Laguiole knife ?

How to sharpen your blade with a sharpening stone?

Your sharpening stone should be wet, immerse it in water until it is fully saturated and bubbles are no longer coming out of it. This should take approximately 5 to 10 minutes.

To use it, hold the knife at a 20° angle against the whetstone and slowly slide each side of the knife against the stone, several times. Most sharpening stone have a rough side and a fine side – start off with the rough side if your knife is particularly blunt then repeat the process on the fine side. If the sharpening stone looks like it is drying out as you work, just pour some more water and keep going.

Watch our cutlery makers in action in this video.

Other sharpening techniques using a stone.

-

How to sharpen a blade with a rod ?

Another accessory which is well-known by fine blades connoisseurs, it is also very efficient to sharpen knives which have lost their original edges.

Discover how to use a sharpening rod in the video below.

-

How to sharpen a knife using a carbide sharpener ?

Pocket carbide sharpeners are incredibly tough, which make them the best pocket sharpeners.

A carbide sharpener deals with all your edges without requiring either oil nor water. Compact, you can always have it on hand, whether you are working, fishing or camping.

Laguiole, by Actiforge.

Are your knives actually made in France ? Are they real Laguiole ?

Yes and yes. Our knives are made in Auvergne by master cutlery-makers from Thiers. Their craftsmanship comes from a long line of Auvergne cutlery-makers, and they keep passing down their passion to the next generations. Of course, some manufacturing techniques have evolved over time, but the belief that what is worth doing is worth doing well and the attention to detail are unchanged.

Which warranties do you offer?

All the Actiforge knives come with a warranty.

Folding knives come with a lifetime warranty.

Table knives have a 2-year warranty.

Our knives are shipped to you with their certificate of origin, so you can know with certainty where your knife comes from : it was Made in France!

Good to know : 85 % of our knives are made in Thiers and 15% in Laguiole, Aveyron.

Laws and counterfeiting.

-

Why was the brand not registered ?

Legally speaking, town names do not belong to anyone, so they belong to everyone. At the time of the first Laguioles, nobody thought about registering the brand and it became part of everyday language, even more than a brand.

Invented in 1829 by Pierre Calmels, in Laguiole, they were then made by local craftsmen who marked them with their names, each of them known for their dedication. At that time, nobody could imagine that this knife’s fame would grow over the centuries !

-

How can I recognize a true Laguiole ?

We are often asked ‘how can I check the authenticity of a Laguiole knife?’…

There is so much to say… This video sums it all up efficiently and concisely.

-

Why is it legal to import Laguiole knives from China?

The Laguiole brand does not fall under an IGPIA (a French Label which stands for Industrial and Artisanal Protected Geographical Indication). Indeed, the ‘Laguiole’ brand was never created because the owner of the Laguiole brand would have had to be in a position to demonstrate that consumers know these knives exclusively thanks to him or her. This is evidently impossible.

This is why a Chinese knife can be called a Laguiole . Consumers who wish to buy quality knives must be very wary.

Legal aspects about the Actiforge Laguiole.

Wondering if our Laguiole are truly French ? We didn’t wait for the launch of the IGPIA standard in 2014 to certify the origins of our cutlery production.

Wondering if our Laguiole are truly French ? We didn’t wait for the launch of the IGPIA standard in 2014 to certify the origins of our cutlery production.

We didn’t wait until PGIs either to certify the authenticity of our knives.

Every year Bureau Veritas inspects our company to guarantee that our Laguiole knives are well and truly made in France, in Thiers. This is how we obtained the Origine France Garantie label.

What are IGPIAs?

IGPIAs (French acronym for Industrial and Artisanal products Geographic Protected Indications) allow consumers to know if a non agri-food product comes from a specific geographic area, when quality, reputation, craftsmanship or other characteristics of the product can be essentially attributed to said geographical origin. The IGPIA also certifies the area of production or processing : everything must be designed and manufactured in the same geographical area.

Questions about real or fake Laguioles ?

-

Are real Laguiole knives exclusively manufactured in Laguiole ?

Nowadays, some knives are indeed manufactured in Laguiole, but it has to be said that most Laguiole blades are made in Thiers. So no, real French Laguiole knives are not exclusively made in Laguiole.

-

My knife has a shepherd’s cross, does this mean it is a real one ?

No, it is simply a decoration. Unfortunately, even some knives which come from Asia possess a shepherd’s cross. A fly, a bee or any other ornament cannot guarantee the quality or origin of your Laguiole. That is why it is necessary to carefully check all the elements of a knife to determine its quality and reliability.

Did you know ? – The shepherd’s cross…

In our region, heavily influenced by the catholic religion, when shepherds travelled to move their flocks to summer pastures, they stuck the blade of their knives in bread. The cross sign then served as an ‘oratory’ for their prayers (it is sometimes also called a shepherd’s rosary). That is why this decoration is only found on one side of the handle.

French legislation on carrying a knife.

In France, the law prohibits carrying any kind of knife, which is considered a 6th category bladed weapon. This prohibition does not take into account the length of the blade or the presence of a locking mechanism.

However, French courts case law considers that carrying a Laguiole knife or and Opinel knife or a swiss-army knife of typical size should not be interpreted as carrying a bladed weapon,. In such cases, carrying a knife is considered as part of the French tradition and is authorized. But depending on the use, it can be upgraded to weapon status.

Depending on the circumstances, police tolerate your having a traditional knife, so long as you show a normal behaviour.

Finally the Vigipirate Plan authorizes spot checks in public places such as underground and train stations. For safety reasons, in places such as airports, policies are stricter and knives may be seized by the police.

General questions about the Laguiole knife.

To give you concise and clear information, the Actiforge team has put together a video which tells the story of the Laguiole knife and its evolution through the ages.

-

Where are Laguiole knives made ?

Laguiole knives can be made everywhere around the globe, however only master cutlery-makers can certify the origin of their products.

Laguiole knives can be made everywhere around the globe, however only master cutlery-makers can certify the origin of their products.

Actiforge Laguiole knives come with a French Origin certificate and a lifetime warranty. You will not find any Laguiole made in Asia with this type of traceability or warranty.

-

Why is there a variety of Laguiole retailers ?

First, it is important to distinguish between ‘knife manufacturers’ (our cutlery makers manufacture the various elements which together form the finished knife) and ‘knife assembler’ (some people merely assemble spare parts made elsewhere).

So there are manufacturers and assemblers – as well as importers, but they are another type altogether…

There’s nothing stopping a company from making or assembling knives, which explains why popular tourist locations sell a variety of knives of sometimes less than impressive quality. Be very careful and only buy knives from a knife manufacturer. They are easy to identify as they are the only ones with a certificate of origins and a several-year warranty (or even lifetime warranty like Actiforge’s).

-

Why is there such a wide range of prices for Laguiole knives?

Just like any other product made for the general public, there is a wide range of Laguioles and therefore a wide range of prices.

Just like any other product made for the general public, there is a wide range of Laguioles and therefore a wide range of prices.

The Laguiole knife design and its name was inherited from our forefathers. Unfortunately they forgot to patent them adequately in time. After 20 years, any product becomes a public product. The legal protection deadline is over. It can’t be protected through a Controlled Designation of Origin label either, since they only apply to food products. As a result, anyone can call anything a Laguiole.

How can I find my way among so many knives ?

Beware of exceedingly good bargains. If you find a very cheap Laguiole knife, it was more than likely manufactured very far away. Quality has a price and the work of a cutlery-maker cannot be compared to that of a machine: you get what you pay for.

Of course, the price of a knife can vary according to its various constitutive elements. Thus an aluminium-handled knife will be cheaper than an abalone-handled one, and a Damascus blade will cost more than a simple one.

Did you know : All the items sold on our website were 100% made in France.

The Veritas certification office audits our company every year and our Laguiole knife are therefore given the ORIGINE FRANCE GARANTIE label.

-

Where can I find a Laguiole knife ?

On Actiforge’s online shop or at a cutlery maker’s shop – in Thiers or Laguiole, of course !

-

How can I tell the difference between a real and a fake Laguiole ?

How do you recognize a Laguiole ? How can you tell that a knife is a real Laguiole? We are often asked these questions!

There are no real or fake Laguiole since Laguiole is not a brand.

Laguiole is the name of a village and refers to a traditional knife design.

The word Laguiole cannot be legally protected.

Laguiole was given ‘generic word’ status by the appeal court of Riom during a lawsuit filed by the cutlery-makers to protect the name.

Some unscrupulous traders took advantage of this legal loophole to use the reputation of quality attributed to this knife to sell mediocre imported goods or even items which had nothing to do with cutlery-making!

This vide ogives you more information on how to check the origin and the quality of a knife. It lists the various items you need to check before buying a Laguiole knife.

-

Which wine best complements the Laguiole ? (didn’t you know ? Laguiole is also the name of a cheese)

The Laguiole cheese is made out of whole raw milk, on the Aubrac plateau in the Southern part of the Massif Central.

The Laguiole cheese is made out of whole raw milk, on the Aubrac plateau in the Southern part of the Massif Central.

Just like any self-respecting cheese, the Laguiole is best served at the end of a meal. A local red wine will work wonders with it, such as a robust AOC Marcillac, a VDQS ENtraygues, or a smooth and silky Le Fel, or even a fruity fresh Estaing. If you prefer Rhône wines, a lovely St Joseph or Brouilly should admirably complement this Auvergne cheese.

-

How did the cutlery makers loose the Laguiole brand ?

The Laguiole knife design and its name was inherited from our forefathers. Unfortunately they forgot to patent them adequately in time.

After 20 years, any product becomes a public product. The legal protection deadline is over. As a result, anyone can call anything a Laguiole.

It can’t be protected through a Controlled Designation of Origin label either, since they only apply to food products.

Short recap of the Laguiole judicial saga.

-

In 1993 Gilbert Szajner, a shrewd businessman from Val de Marne registers the Laguiole brand. It does not only apply to cutlery but also to a variety of other items: linen, clothes, lighters, barbecues…

The village of Laguiole refuses to tolerate that its name be used and starts a lawsuit. -

In 2012, despite many procedures filed by the town of Laguiole, Gilbert Szajner ‘s position is upheld by the court since ‘Laguiole is a noun used to refer to a knife which is now part of everyday language and without any obvious and direct link to the town of Laguiole’ The village then files another, wider suit about its name – Auvergne people never give up!

In 2012, despite many procedures filed by the town of Laguiole, Gilbert Szajner ‘s position is upheld by the court since ‘Laguiole is a noun used to refer to a knife which is now part of everyday language and without any obvious and direct link to the town of Laguiole’ The village then files another, wider suit about its name – Auvergne people never give up! -

In a ruling made on April 4th 2014, the Paris court of appeal denies the demands of the town of Laguiole who wanted the judicial system to admit that there had been ‘a misleading commercial practice’ and ‘a prejudice to its name, its image and its reputation’.

M. Szajner can keep on distributing, in exchange for money, licenses to French or foreign companies who can then sell imported goods under the name ‘Laguiole’

However, the inhabitants of Laguiole, cannot use the name of their village any longer to produce manufactured goods with the ‘Laguiole’ label, except for the bee-bearing knife, which is already being manufactured outside of the village. -

In 2018, a new battle began, which opposes the proponents of the Laguiole PGI